ABOUT US

A START-UP

WITH 50 YEARS OF HISTORY

A START-UP

WITH 50 YEARS OF HISTORY

D-Air Lab was founded by Lino Dainese in 2015 as an innovative start-up with the goal of identifying new applications of D-air®, the sophisticated personal protective airbag technology developed by Dainese.

2024

The first official supply of Antarctic equipment was delivered to the Italian ENEA research team.

2024

Our commitment to innovation and design is recognised with major awards: FutureAge and the Cooperation Suit are selected for the ADI Design Index, and the Antarctic Suit receives the IF Design Award.

2024

The launch of FutureAge, airbag belt for the elderly, introduces a new standard in everyday personal protection.

2023

Technologies developed for researchers in Antarctica are adapted to create lighter garments suitable for everyday wear, resulting in the technical winter clothing brand 75°06’S.

2022

WorkAir wins the ADI Design Index Innovation Award. Three key words guided the choice: freedom, quality and system.

2022

D-Air lab collaborates with Dior for the realization of some garments on the occasion of the autumn-winter 2022-2023 fashion show for the prêt-à-porter line held in Paris.

2021

The Antarctica suit is presented at the Venice Architecture Biennale in the exhibition Antarctic Resolution, curated by Giulia Foscari / UNLESS

2018

D-Air lab delivers to Enel the first prototypes of WorkAir, the airbag for the protection of workers. Field tests begin.

2015

D-Air lab is founded with Lino Dainese holding 75% of the share capital and Dainese Spa holding the remaining 25%.

2012

Dainese presents D-Air Ski, the airbag for alpine ski athletes, at Kitzbühel. D-Air Ski is subsequently adopted by the Austrian, Swiss and Italian Federations amongst many others.

2011

D-air® launches on the international market in Racing and Street versions for use on the track and road respectively.

2007

Dainese partners with Professor Dava Newman and Space Architect Guillermo Trotti to design the Biosuit, a space suit that applies pressure to the astronaut's body without restricting their freedom of movement.

2000

Dainese presents the first prototype of the D-Air airbag for protecting motorcyclists.

1995

Dainese back protectors and armour are adopted by alpine ski and downhill mountain bike athletes.

1979

Lino Dainese invents and patents the first back protector

1972

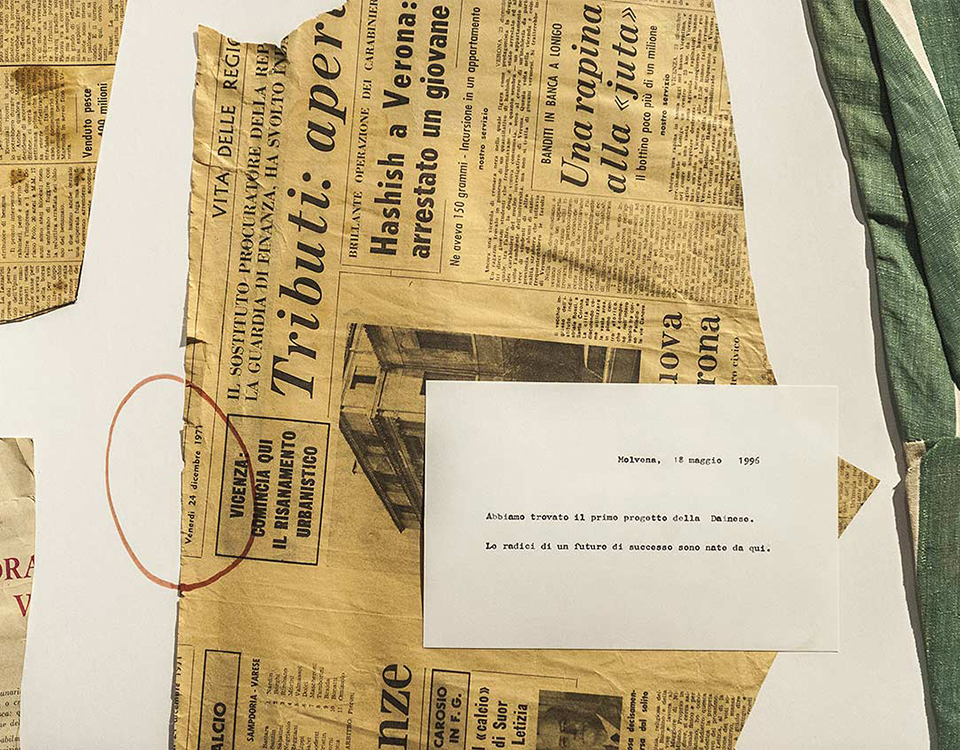

Lino Dainese establishes Dainese "Motorcycle suits" in Molvena (Vincenza), Italy.

DAR

The DAR – Dainese ARchive – tells the 50-year history of Dainese, showing visitors the ideas, technologies, people and innovations that took Dainese to become a leader in its sector. Rich in that experience, D-Air Lab is on a new journey, the first steps in which have already been taken while the final destination is still unknown.

OUR WORKING FRIENDS

CONTACTS