Safety in the workplace is a vital aspect for every company that operates in high-risk sectors, especially when it is a question of work at heights. Personal protective equipment (PPE) plays a crucial role in this situation, as it acts as a shield between the worker and potential hazards.

It is not enough just to provide the PPE, it is also essential to understand in full the obligation of maintenance of personal protective equipment and the strict standards that govern it, particularly UNI EN 365, which focuses on fall protection PPE (category III PPE).

Personal protective equipment: more than just a simple aid

Personal protective equipment is not just a simple aid, but comprises genuine devices designed to save lives. Whether these are helmets, gloves, protective goggles or, in the case of work at heights, harnesses and fall arrest systems, their efficacy depends not only on the quality of the product at the moment of purchase, but also on correct and periodic maintenance.

It is precisely for category III PPE that the control and maintenance procedures become extremely strict. A malfunction of these devices could have fatal consequences, so ensuring that they are undamaged and functioning correctly really is a question of life or death.

The obligation placed on the employer: management of PPE

The Italian law on occupational health and safety (Legislative Decree no. 81/08) establishes that the employer is entirely responsible both for the management of personal protective equipment and for the related expenses. This means that the employer has the obligation of assessing the hazards present in the workplace and identifying the most appropriate PPE, providing it free of charge to workers, ensuring they receive proper training and also supervising its correct use and guaranteeing its maintenance, repair and replacement when necessary, ensuring that it is efficient and in a good state.

PPE expiry dates: a regulatory requirement

The PPE expiry dates, particularly the ones intended for fall protection, is clearly indicated by the manufacturer. This is not an arbitrary date, but rather it is based on strict tests that assess the resistance and reliability of the materials over time. Exposure to environmental factors such as UV rays, humidity, sudden changes in temperature, dust and chemicals, in addition to wear and tear, can irredeemably damage PPE.

Ignoring the expiration date of a safety harness or any other component of the fall arrest system constitutes not only a breach of safety regulations, but also an unacceptable risk for the worker. It is therefore essential for every company to keep an accurate register of the PPE provided, to monitor the purchase dates and the expiration dates and to plan regular safety harness inspections.

Standard UNI EN 365 on periodic inspections

Fall protection PPE maintenance procedures are governed by standard EN 365, transposed into Italian regulations as UNI EN 365. This regulation is vitally important, as it establishes the minimum requirements for user instructions, maintenance, periodic inspection, repair and marking of all personal protective equipment used for fall protection.

The employer is responsible for correct application of the provisions of UNI EN 365, ensuring that the PPE is suitable for use, that efficient maintenance is performed on it and that the workers have been properly trained in its use and maintenance.

By way of summary, the requirements of UNI EN 365 are that:

- The user and maintenance instructions provided by the manufacturer are clear and comprehensible.

- Periodic controls are performed by a skilled person, with a frequency of no less than 12 months, or more frequently in the case of intensive use or particularly hazardous environments.

- Repairs are performed only by the manufacturer or by a person authorised by it, using exclusively original replacement parts.

- The marking of the PPE indicates all the information necessary for its identification and traceability.

Application of UNI EN 365 is both a legal obligation and an investment in workers’ safety and in the company’s reputation. A properly organised PPE maintenance schedule guarantees that the equipment is always in perfect conditions of operation and ready to intervene when needed.

WorkAir: a new paradigm of innovation and safety

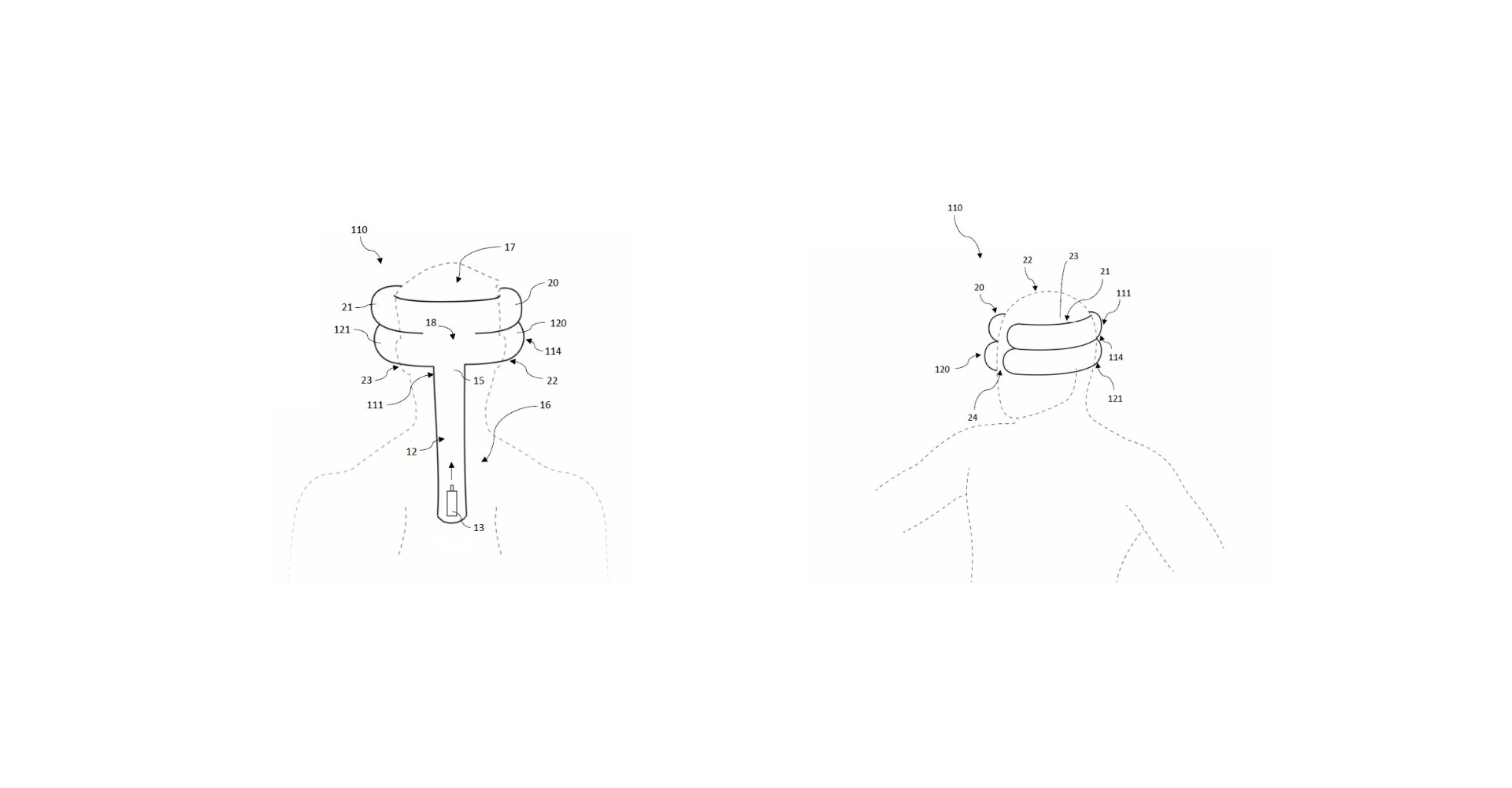

On such a complex and highly regulated panorama as safety in work at heights, WorkAir stands apart as a wearable airbag designed to protect workers.

WorkAir is classified as category II PPE, as it is not a fall protection system, and operates with a different concept to the traditional PPE in the same segment. It is not a system to “arrest” the fall in the traditional sense (such as a harness or a cord), but rather a protector that intervenes by reducing the force of the impact against the hard surfaces that could be encountered precisely during a fall. This substantial difference also influences the maintenance procedures.

In fact, in contrast with category III fall protection PPE, for which there is an obligation of mandatory periodic controls and annual inspections in strict compliance with UNI EN 365, WorkAir is not subject to any mandatory periodic maintenance. However, in order to guarantee it remains totally efficient and to extend the warranty, we recommend performing an inspection of the parts subject to wear and tear every 3 years.

This results in a considerable saving of time and resources for companies, while still maintaining an extremely high standard of safety.

Contact our experts to learn more about WorkAir!