Falls from heights of over two metres are one of the main causes of serious or fatal injuries at work sites and in other work environments: according to the most recent figures from the Inail (Italian National Institute for Insurance against Accidents at Work), in fact, 30% of accidents in the building industry are the result of crushing in vertical or horizontal movement against an immobile object (falls from a height in 9 cases out of 10). In order to reduce these risks, it is essential to use Personal Protective Equipment, or PPE. In detail, the PPE for work at height is category III PPE, which guarantees protection against deadly hazards or irreversible damage to the worker’s health.

In this article, we are taking a look at the features of category III PPE for work at height and the regulatory requirements on its use and maintenance.

PPE in categories I, II and III

Before examining in detail category III PPE for work at height, it is necessary to take a step back and understand what PPE is and the differences between the various categories. Personal Protective Equipment is designed to protect workers against risks that cannot be eliminated with collective protective measures. It is divided into three categories, based on the level of risk against which it provides protection:

- Category I PPE: equipment intended to protect workers against minor risks. Examples are gardening gloves and sunglasses.

- Category II PPE: includes equipment that protects against risks of medium seriousness. This includes work helmets, protective goggles and cut-resistant gloves.

- Category III PPE: this equipment is designed to protect workers against serious or life-threatening risks. This includes equipment such as breathing apparatus, harnesses and fall arrest systems for work at height.

Category III PPE

What exactly is meant by “serious or fatal risks”? They include:

• substances and mixtures hazardous to health;

• oxygen-deficient atmospheres;

• harmful biological agents;

• ionising radiation;

• high-temperature environments (at least 100°C);

• low-temperature environments (-50°C or lower);

• falls from heights;

• electric shocks and working under voltage;

• drowning;

• cuts from portable chain saws;

• high-pressure jets;

• bullet or knife wounds;

• harmful noise.

Category III PPE for work at height

Falls from height are among the serious and fatal risks and therefore, to provide the maximum possible protection for workers at height, the use of third category PPE is mandatory.

The main types of this PPE are examined below.

Harnesses.

These are essential for working safely at height, as they provide a reliable retention system, essential to avoiding the serious consequences of a fall. Harnesses allow workers to operate in conditions of the utmost safety and to move easily, since they are designed to allow a total freedom of movement during work activities. The most common types are ventral harnesses, which have rear anchoring devices and double groin holes.

Fall arrest systems

These are essential for guaranteeing the safety of workers at height, since they block any falls in a controlled manner. They comprise a set of components, such as safety cords, retractors and energy absorbers, that work together with the harness to reduce the impact of the fall and reduce the risk of serious injury. Fall arrest systems allow workers to perform their activities at height with greater peace of mind, as they know they are protected in the case of accidents. Their design makes them practical and easy to use when working.

Helmets

This is probably the most common equipment in this category, as helmets are necessary in numerous industries. The purpose of a helmet is to protect the head both against accidental falls and against material falling from a height. Certified helmets that are compliant with regulations have an under-chin fastening system that prevents them from slipping. The most advanced models might have a visor to protect the eyes against irritants, acoustic protectors to protect the hearing, and may also be equipped with masks for protection of the airways.

Anchoring systems

Anchoring systems provide secure connection points to which to attach the Personal Protective Equipment. Various types of anchoring systems exist, and offer a flexibility based on the needs of the work site. These systems can be installed permanently on structures such as buildings or used temporarily at specific work sites. The anchors must be sturdy and compliant with current regulations, in order to ensure that they support the weight and the forces generated in the case of a fall.

Limitations of Category III PPE

Unfortunately, even the best category III PPE cannot completely eliminate the risk of falls from a height. There are, in fact, various factors that contribute to increasing the possibility of serious accidents occurring, such as:

- Lack of training: Training is mandatory for use of category III PPE and must be provided by qualified professionals. Incorrect use caused by a lack of technical skills can considerably increase the risk of accidents.

- Environmental conditions: Strong wind, heavy rain, ice and other adverse weather conditions can undermine safety, even when appropriate PPE is being used.

- Maintenance and wear and tear of PPE: PPE must be maintained in perfect conditions Wear and tear or damage to the equipment can reduce its efficacy.

- Correct installation: Anchoring systems and attachment points must be correctly installed and used. Incorrect installation can make this equipment less reliable.

- Risky behaviour: Taking risks or being unaware of safety procedures can certainly defeat the beneficial purposes of PPE.

- Residual risk: the application of prevention and protection measures significantly reduces the initial risk, but does not eliminate it entirely in most cases.

- Absence of anchoring points: it could be that, in certain situations of work at height (such as maintenance operations on vehicles or aircraft), the above PPE cannot be used, as there are no attachment points.

A strategy to reduce the risk of accidents could be to use certain category II PPE as additional protection. This equipment can help both in improving overall safety when used in combination with category III PPE and in mitigating the consequences of a fall.

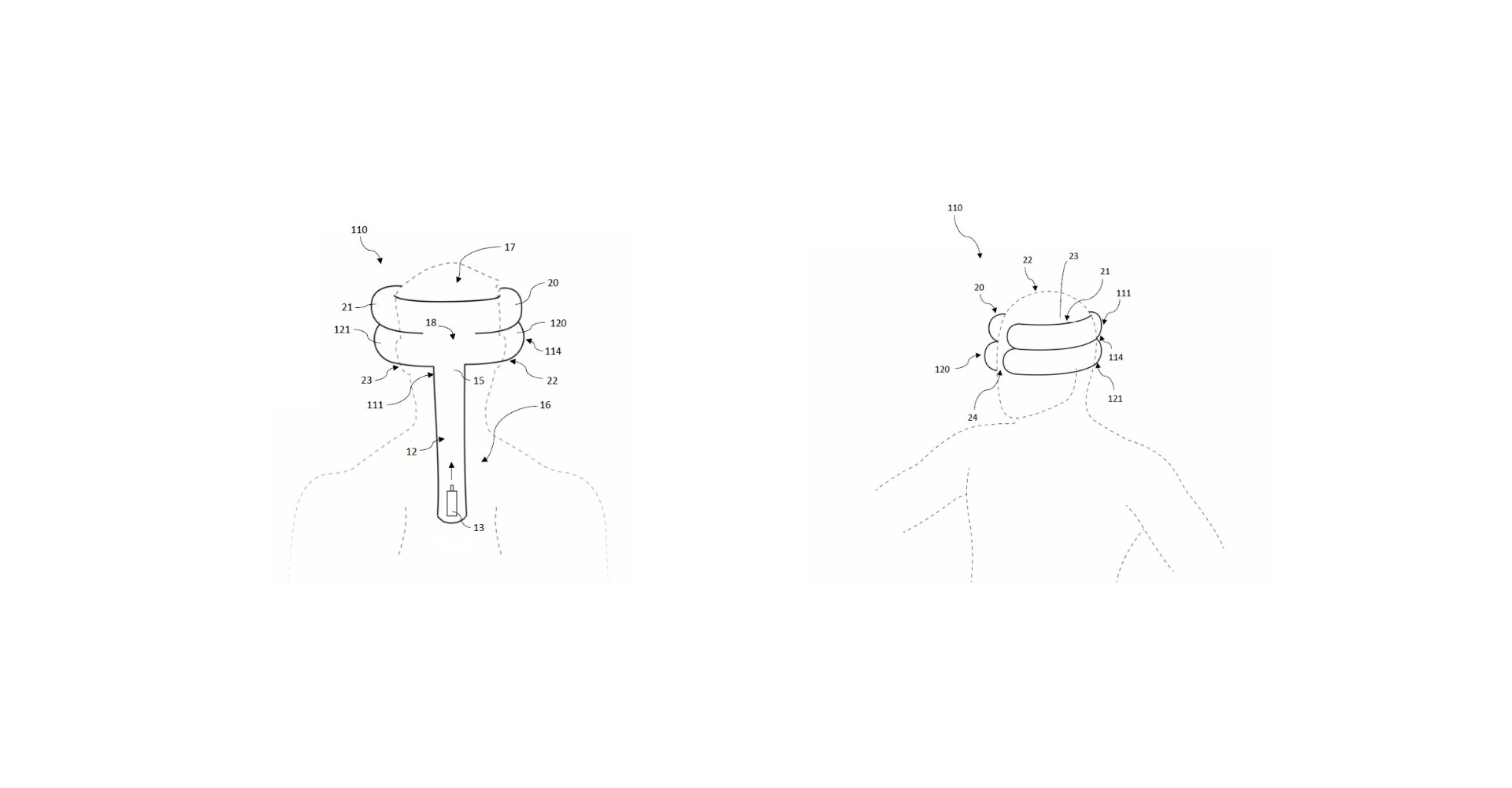

A device that is useful in this sense is WorkAir, an airbag wearable as a normal item of clothing and that, thanks to the sensors and the electronically activated algorithm, is able to detect the conditions for a potential fall with a high degree of precision and inflate accordingly. This effectively protects the worker’s back and chest from impact with the ground or from the pendulum effect against the surrounding structures, without affecting comfort.